CMC Rope Rescue Manual: A Comprehensive Article Plan

CMC’s fifth edition‚ published in 2026‚ boasts 430 pages‚ including 40 new ones‚ and serves as the definitive guide for rope rescue professionals and enthusiasts.

The CMC Rope Rescue Technician Manual has firmly established itself as the gold standard reference for countless fire departments‚ search and rescue teams‚ and specialized industrial rope access programs. This comprehensive resource isn’t simply a compilation of techniques; it’s a distillation of over four decades of practical experience gleaned from real-world rescue operations and the instruction of thousands of students.

Published by CMC Rescue‚ Inc.‚ located in Goleta‚ California‚ and authored by LeRoy Harbach and Cedric Smith‚ the manual provides a detailed and systematic approach to rope rescue. It’s designed for a broad spectrum of professionals – from firefighters and search and rescue technicians to cave rescue personnel and high-angle rescue workers – and anyone actively involved in technical rescue scenarios within challenging‚ high-angle environments.

Target Audience and Applications

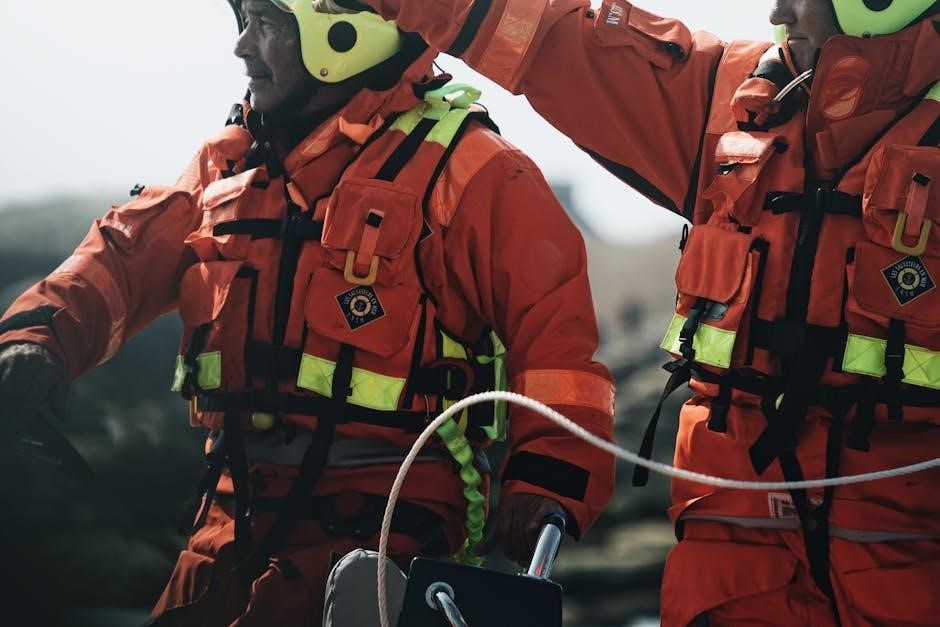

This manual is meticulously crafted for a diverse range of professionals directly involved in technical rescue operations. The primary target audience encompasses firefighters requiring specialized rope rescue skills‚ dedicated search and rescue technicians responding to complex incidents‚ and individuals engaged in industrial rope access work where safety is paramount.

Furthermore‚ the manual serves as an invaluable resource for cave rescue personnel navigating subterranean challenges‚ high-angle rescue workers operating in mountainous or vertical environments‚ and anyone participating in rescue efforts within high-angle settings. Its applications extend beyond emergency response‚ proving beneficial for training programs and continuous professional development‚ ensuring practitioners are equipped with the latest techniques and safety protocols.

Overview of the Fifth Edition Updates (2026)

The 2026 fifth edition of the CMC Rope Rescue Manual incorporates significant updates reflecting advancements in rescue techniques and industry standards. Notably‚ NFPA 1006 references have been integrated into both Terminal and Enabling Learning Objectives within each chapter‚ enhancing clarity and compliance.

A key restructuring involves separating High Angle and Low Angle rescue chapters from the Litter Operations section‚ providing focused guidance. Dedicated coverage is now included for Twin Tension Systems and Ladder Rescue Systems. The Rope Access chapter features updated‚ step-by-step illustrations for improved comprehension‚ alongside new techniques for the CMC CLUTCH by Harken Industrial. User information for the CLUTCH‚ LEVR‚ G11 Lifeline‚ ASORP‚ and Hurley Picket is also included‚ totaling 40 new pages within the 430-page manual.

Part 1: Foundations of Rope Rescue

This section establishes core principles‚ safety protocols‚ and relevant standards like NFPA 1006‚ alongside crucial life safety equipment testing and certification details.

Chapter 1: Learning Rope Rescue – Core Principles

This foundational chapter delves into the essential concepts underpinning safe and effective rope rescue operations. It emphasizes a systematic approach to rescue‚ prioritizing risk assessment and hazard mitigation. Learners will explore the importance of understanding load distribution‚ friction management‚ and the mechanical advantages gained through proper system design.

The chapter stresses the need for continuous learning and adaptation‚ acknowledging that every rescue scenario presents unique challenges. It introduces the concept of building a strong mental model of rope systems‚ enabling rescuers to predict behavior and troubleshoot potential issues. Furthermore‚ it highlights the critical role of teamwork‚ communication‚ and adherence to established protocols in ensuring successful outcomes. Mastering these core principles is paramount for any aspiring rope rescue technician.

Chapter 2: Safety Protocols in Rope Rescue Operations

This critical chapter establishes the paramount importance of safety throughout all phases of a rope rescue. It details comprehensive protocols designed to minimize risk to both the rescuer and the subject. Emphasis is placed on pre-rescue planning‚ including thorough site assessments and hazard identification.

The chapter outlines procedures for establishing a robust safety zone‚ implementing effective communication systems‚ and utilizing appropriate personal protective equipment (PPE). It also addresses the importance of regular equipment inspections and maintenance. Detailed guidance is provided on managing fall factors‚ understanding load limits‚ and implementing backup systems. Adherence to these protocols is non-negotiable‚ forming the bedrock of responsible and ethical rope rescue practice.

Chapter 3: Standards and Regulations (NFPA 1006)

This chapter provides a detailed examination of the relevant standards and regulations governing rope rescue operations‚ with a primary focus on NFPA 1006‚ Standard for Technical Rescue Personnel. It clarifies the requirements for training‚ competency‚ and certification of rescue technicians.

The manual integrates NFPA 1006 references directly into the Terminal and Enabling Learning Objectives within each chapter‚ ensuring alignment with industry best practices. It explains how adherence to these standards enhances safety‚ promotes consistency‚ and facilitates interoperability between different rescue teams. Understanding and complying with NFPA 1006 is crucial for legal defensibility and maintaining a high level of professional competence in the field of technical rescue.

Chapter 4: Life Safety Equipment Testing & Certification

This crucial chapter delves into the rigorous testing and certification processes for all life safety equipment utilized in rope rescue operations. It emphasizes the importance of understanding manufacturer specifications‚ inspection criteria‚ and retirement guidelines to ensure equipment reliability and user safety.

The manual details the standards governing rope‚ webbing‚ carabiners‚ pulleys‚ harnesses‚ and other essential gear. It explains how proper testing verifies that equipment meets or exceeds established performance benchmarks. Technicians learn to identify signs of damage or wear that could compromise equipment integrity‚ and the chapter stresses the necessity of removing compromised equipment from service immediately. Regular inspection and adherence to certification protocols are paramount for mitigating risk and ensuring successful rescue outcomes.

Part 2: Essential Rope Rescue Equipment

This section meticulously examines life safety ropes‚ webbing‚ hardware like carabiners and pulleys‚ and crucial personal gear—harnesses‚ helmets‚ and ascenders.

Chapter 5: Life Safety Rope and Webbing – Types and Usage

This chapter provides an in-depth exploration of life safety rope and webbing‚ detailing the various types available to rescue professionals. It covers static versus dynamic ropes‚ construction methods‚ and their specific applications within rope rescue scenarios. Understanding the properties of different rope materials – like nylon and polyester – is crucial for selecting the appropriate rope for a given task.

Furthermore‚ the chapter delves into webbing‚ outlining its strengths and limitations‚ and demonstrating its versatile uses in anchor construction and patient packaging. Detailed information is provided on rope inspection criteria‚ proper care and maintenance procedures‚ and the importance of adhering to manufacturer specifications to ensure optimal performance and longevity. Proper rope management techniques are also emphasized to prevent damage and extend the rope’s service life.

Chapter 6: Rope Rescue Hardware – Carabiners‚ Pulleys‚ and More

This chapter comprehensively examines the essential hardware components utilized in rope rescue operations. It begins with a detailed analysis of carabiners – their various shapes‚ locking mechanisms‚ and strength ratings – emphasizing proper selection based on intended use. The chapter then explores different types of pulleys‚ including mechanical advantage systems and their applications in hauling and lowering loads.

Beyond carabiners and pulleys‚ it covers other critical hardware like hitches‚ descenders‚ and specialized connectors. Emphasis is placed on understanding load distribution‚ proper hardware orientation‚ and the importance of regular inspection for wear and damage. Compatibility between different hardware components is also addressed‚ ensuring safe and reliable system construction. The chapter reinforces the need for adhering to manufacturer guidelines and industry standards.

Chapter 7: Personal Equipment – Harnesses‚ Helmets‚ and Ascenders

This crucial chapter details the personal protective equipment (PPE) vital for rescuer safety. It begins with an in-depth look at harnesses‚ covering different types – full-body‚ seat‚ and chest – and proper fitting procedures to ensure comfort and security during operations. The chapter then focuses on helmets‚ emphasizing impact protection and the importance of selecting a helmet certified to relevant safety standards.

Ascenders are thoroughly examined‚ detailing their mechanics‚ proper attachment techniques‚ and safe usage for ascending ropes. Beyond these core items‚ the chapter addresses other essential PPE like gloves‚ footwear‚ and protective eyewear. Regular inspection‚ maintenance‚ and proper storage of all personal equipment are stressed‚ reinforcing a culture of safety and preparedness for all rescue personnel.

Part 3: Fundamental Rope Rescue Skills

This section covers essential techniques‚ including knot tying‚ anchor construction‚ edge protection‚ patient packaging‚ and litter operations – building a solid foundation.

Chapter 8: Essential Knots for Rope Rescue

Mastering knots is paramount in rope rescue‚ forming the bedrock of any secure system. This chapter meticulously details crucial knots‚ emphasizing their specific applications within rescue scenarios. Expect comprehensive instruction on bends‚ hitches‚ and loops‚ each explained with clarity and illustrated for easy comprehension.

Beyond simple tying‚ the chapter delves into knot security‚ limitations‚ and appropriate usage based on rope type and load. Understanding how each knot behaves under stress is critical for safety. Detailed diagrams and step-by-step instructions will guide users through the proper execution of each knot‚ ensuring reliability in demanding situations.

Furthermore‚ the chapter will likely cover knot testing and inspection procedures‚ reinforcing the importance of verifying knot integrity before committing to a rescue operation. This foundational knowledge empowers rescuers to build robust and dependable systems.

Chapter 9: Anchor Construction – Single Point Anchors

Establishing a solid anchor is the first‚ and arguably most critical‚ step in any rope rescue operation. This chapter focuses specifically on constructing single-point anchors‚ the foundational building blocks for more complex systems. It will detail various methods for creating secure anchors using natural features‚ structural elements‚ and specialized equipment like the Hurley Picket.

Emphasis will be placed on evaluating anchor strength and identifying potential failure points. The chapter will cover proper material selection‚ load distribution‚ and equalization techniques to maximize anchor integrity. Understanding the forces involved and how they impact the anchor is paramount.

Detailed illustrations and practical examples will demonstrate how to build reliable single-point anchors in diverse environments‚ ensuring rescuers can confidently establish a secure foundation for their operations.

Chapter 10: Building Complex Anchor Systems

Beyond single-point anchors‚ many rescue scenarios demand more sophisticated systems capable of handling greater loads and providing redundancy. This chapter delves into the construction of complex anchor systems‚ building upon the foundational principles established in the previous chapter.

Techniques for creating multi-point anchors‚ load-sharing systems‚ and equalization methods will be thoroughly explored. The importance of minimizing force on individual anchor components and maximizing overall system strength will be highlighted. Practical applications for various rescue situations will be presented.

Detailed diagrams and step-by-step instructions will guide users through the process of building robust and reliable complex anchor systems‚ ensuring rescuer safety and operational effectiveness. Understanding the principles of force vectors and load distribution is crucial.

Chapter 11: Edge Protection Techniques

Sharp edges pose a significant threat to rope systems‚ potentially causing abrasion‚ cutting‚ and catastrophic failure. This chapter focuses on the critical importance of edge protection in rope rescue operations‚ detailing various techniques to mitigate these risks.

Methods for padding edges with specialized materials‚ creating deflection angles‚ and utilizing edge protectors will be comprehensively covered. The selection of appropriate edge protection based on rope type‚ load‚ and edge sharpness will be emphasized. Understanding material strengths and limitations is paramount.

Practical demonstrations and real-world examples will illustrate effective edge protection strategies‚ ensuring the longevity and integrity of rescue systems. Proper inspection and maintenance of edge protection equipment will also be addressed‚ safeguarding both rescuers and the patient.

Chapter 12: Patient Packaging Methods

Secure and efficient patient packaging is crucial for a successful rope rescue. This chapter details various techniques for immobilizing and preparing a patient for vertical transport‚ prioritizing comfort and minimizing further injury.

Methods covered will include the use of backboards‚ litters‚ and specialized packaging devices‚ adapting to different patient conditions and terrain challenges. Proper spinal immobilization protocols‚ head and neck support‚ and securing the patient to the chosen transport device will be thoroughly explained.

Emphasis will be placed on maintaining patient airway‚ circulation‚ and preventing movement during the packaging process. Considerations for patients with specific medical conditions‚ such as fractures or trauma‚ will also be addressed‚ ensuring a safe and controlled ascent or descent.

Chapter 13: Litter Operations – Selection and Implementation

This chapter focuses on the critical aspects of litter operations in rope rescue scenarios‚ covering selection criteria based on the rescue environment and patient needs. Different litter types – from flexible to rigid – will be examined‚ detailing their advantages and disadvantages for various applications.

Implementation techniques‚ including proper rigging for raising and lowering litters‚ maintaining patient security‚ and team communication protocols‚ are thoroughly explained. Considerations for managing litter swing‚ controlling descent rates‚ and adapting to challenging terrain will be addressed.

Emphasis is placed on safe and efficient litter handling‚ minimizing patient discomfort‚ and ensuring the safety of the rescue team. The chapter will also cover techniques for transferring patients to and from the litter‚ and integrating litter operations with other rope rescue systems.

Part 4: Advanced Rescue Systems

This section details complex techniques like twin tension‚ ladder rescues‚ and specialized equipment – LEVR‚ G11‚ ASORP‚ and Hurley Picket usage.

Chapter 14: Twin Tension Systems – Principles and Application

Twin tension systems represent a significant advancement in rope rescue‚ offering enhanced safety and versatility for complex scenarios. This chapter meticulously explores the foundational principles governing these systems‚ detailing how to distribute loads effectively between two ropes.

Readers will gain a comprehensive understanding of the mechanics involved‚ including the advantages of redundancy and the mitigation of shock loading. Practical application is emphasized‚ with step-by-step instructions for constructing and deploying twin tension setups in various rescue environments.

The manual provides detailed illustrations and real-world examples‚ ensuring technicians can confidently implement these systems. Emphasis is placed on proper anchor selection‚ rope compatibility‚ and the critical importance of thorough system checks before and during operations. This chapter is entirely new to the fifth edition.

Chapter 15: Ladder Rescue Systems – Techniques and Safety

This dedicated chapter focuses on the integration of ladders into rope rescue operations‚ providing a crucial skillset for technicians responding to diverse emergency situations. It details techniques for safely ascending and descending ladders while burdened with rescue equipment or a patient.

The manual emphasizes the importance of ladder stabilization‚ proper angle selection‚ and effective communication between team members. Specific attention is given to scenarios involving limited access or challenging terrain where ladder systems offer a viable rescue solution.

Safety protocols are paramount‚ with detailed guidance on load calculations‚ fall protection‚ and hazard assessment. Updated techniques and illustrations ensure technicians are equipped with the knowledge to execute ladder rescues efficiently and securely. This is a brand-new addition to the fifth edition.

Chapter 16: CMC CLUTCH by Harken Industrial – User Information

This chapter provides comprehensive user information for the innovative CMC CLUTCH by Harken Industrial‚ a device designed to enhance rope rescue efficiency and safety. It details the CLUTCH’s mechanics‚ focusing on its ability to provide controlled descent and ascent capabilities for rescuers and patients.

The manual includes step-by-step instructions on proper rigging‚ operation‚ and maintenance of the CLUTCH‚ alongside troubleshooting guidance for common issues. Newly developed techniques are presented‚ showcasing advanced applications for this versatile piece of equipment.

Emphasis is placed on understanding the CLUTCH’s limitations and implementing appropriate safety measures. Detailed illustrations and practical examples ensure technicians can confidently integrate the CMC CLUTCH into their rescue protocols‚ maximizing its benefits in challenging scenarios.

Chapter 17: Specialized Equipment – LEVR‚ G11 Lifeline‚ ASORP‚ Hurley Picket

This chapter delves into the specifics of several specialized rescue tools: the LEVR Personal Escape System‚ CMC G11 Lifeline‚ ASORP (Omni Directional Rigging Pod)‚ and the Hurley Picket Anchor System. Each section provides detailed user information‚ covering proper deployment‚ operational procedures‚ and safety considerations.

The manual explains the unique advantages of each device‚ highlighting scenarios where their use is most effective. For instance‚ the LEVR is presented as a crucial self-rescue tool‚ while the ASORP offers versatile rigging options.

Detailed diagrams and practical examples illustrate how to integrate these tools into complex rescue systems‚ ensuring technicians can confidently utilize them to enhance safety and efficiency in demanding environments. Emphasis is placed on understanding limitations and conducting regular equipment checks.

Chapter 18: Rope Access Techniques – Step-by-Step Illustrations

This chapter focuses on the practical application of rope access methods‚ providing a visual guide to various techniques. The fifth edition features updated‚ step-by-step illustrations designed to clarify complex procedures and ensure proper execution. These visuals demonstrate everything from basic ascents and descents to more advanced maneuvers.

The manual emphasizes safety protocols throughout‚ highlighting potential hazards and mitigation strategies. Detailed explanations accompany each illustration‚ covering equipment selection‚ knot tying‚ and anchor placement.

Technicians will find clear guidance on establishing and maintaining a secure rope system‚ enabling efficient access to difficult-to-reach locations for rescue or work purposes. The illustrations are intended to be a valuable resource for both training and on-site reference.

Chapter 19: High Angle vs. Low Angle Rescue – Distinctions and Procedures

This crucial chapter delineates the fundamental differences between high-angle and low-angle rescue scenarios‚ recognizing that each demands unique techniques and equipment. Previously integrated within the Litter Operations chapter‚ it now stands alone for focused instruction.

The manual details how to assess the angle of descent‚ influencing anchor selection‚ rope system configuration‚ and patient packaging methods. It emphasizes the importance of understanding mechanical advantage and load distribution in both environments.

Technicians will learn to adapt their skills based on the specific angle‚ ensuring a safe and efficient rescue. Detailed procedures are provided for each scenario‚ covering everything from rope rigging to patient evacuation‚ promoting competency and preparedness.